IPC-2152 Standard: The Definitive Guide for PCB Trace Width Calculations

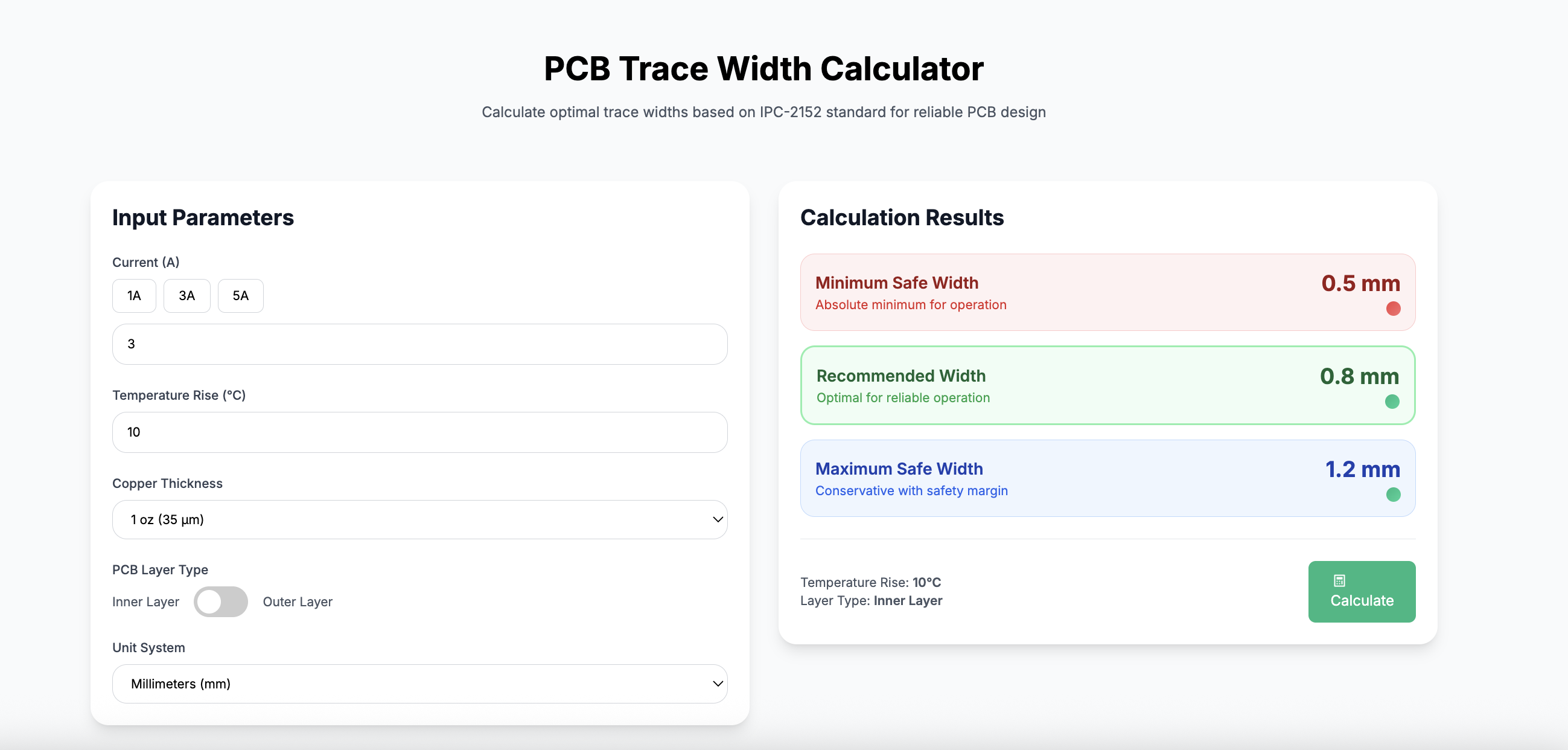

The IPC-2152 standard revolutionized PCB design by providing accurate methods for trace width calculation. This guide explains how to apply it using our PCB Trace Width Calculator.

Key Improvements Over IPC-2221

IPC-2152 introduced significant advancements:

-

More accurate thermal modeling

-

Consideration of board material properties

-

Experimental validation with modern materials

The Fundamental Equation

The core formula in IPC-2152 for internal layers:

Width (mm) = (Current × 0.024) / (TemperatureRise^0.44)Where our calculator automatically handles:

-

Current in Amperes

-

Temperature rise in °C

-

Copper weight adjustments

Practical Application

Example for a 5A power supply with 20°C rise:

1oz Copper

Width: 1.2mm

Using standard FR4 material

2oz Copper

Width: 0.84mm

30% reduction possible

Design Tip

Verify your calculations with our IPC-2152 compliant calculator before manufacturing.

Advanced Considerations

Parallel Traces

Multiple traces sharing current require spacing equal to their width

High Frequency Effects

Skin effect becomes significant above 10MHz

Via Current Capacity

Vias have different current limits than traces

Mastered IPC-2152? Try our advanced calculator features for complex designs.

Back to Blog