Practical Applications of PCB Trace Width Calculator in Modern Electronics

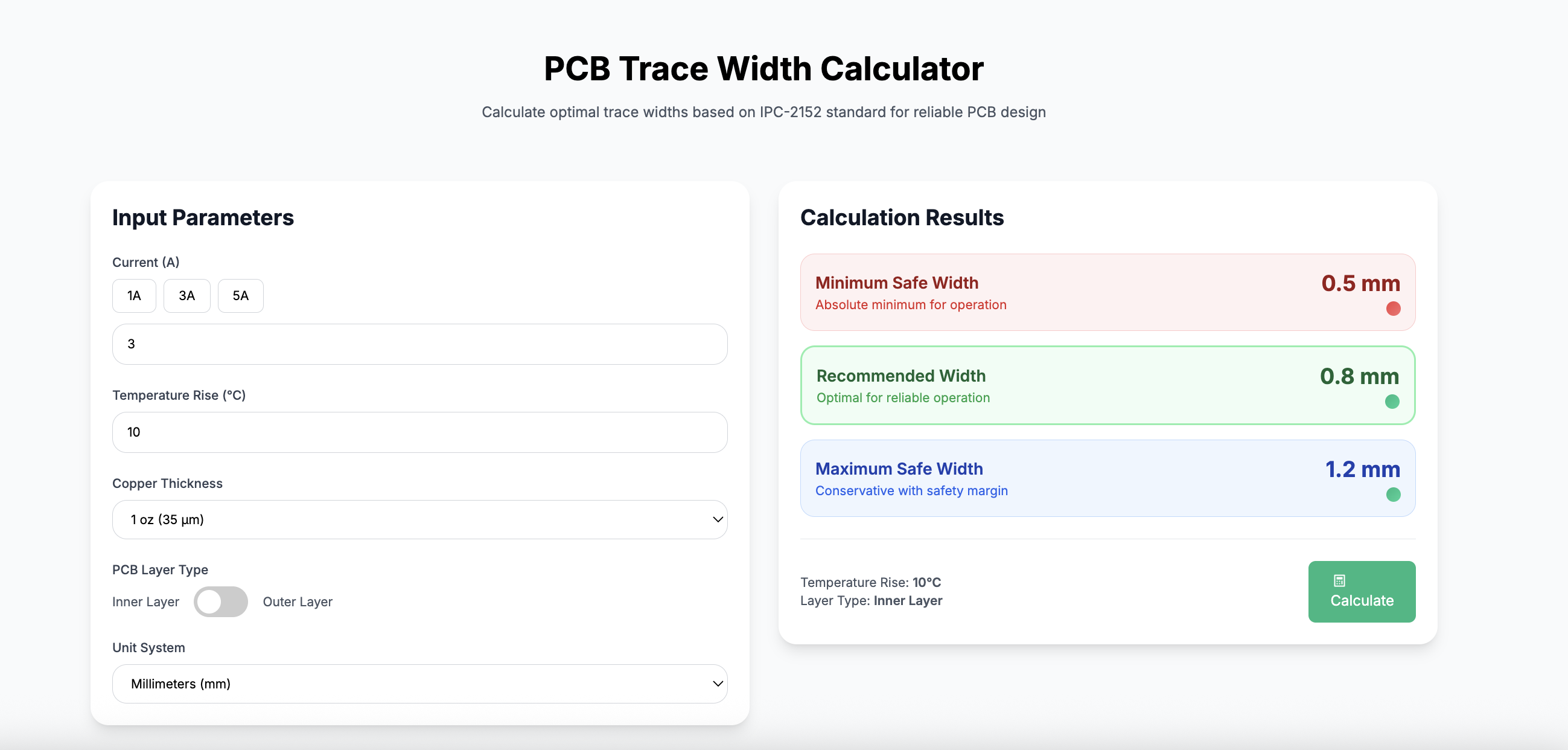

Proper trace width calculation is essential for reliable PCB designs. This article explores real-world applications of PCB trace width calculators across various industries.

Power Electronics Applications

In power electronics, accurate trace width calculation prevents overheating and ensures efficient current flow. Key considerations:

-

High current applications (10A+) require careful calculation

-

Thermal management impacts trace width requirements

Example: Motor Driver PCB

For a 15A motor driver with 20°C max temperature rise:

// Using our PCB Trace Width Calculator

Current: 15A

Temp Rise: 20°C

Copper: 2oz

Result: 3.2mm minimum widthConsumer Electronics

Space-constrained designs require balancing current capacity with PCB real estate:

Smartphone Charging Circuit

2A charging circuit with 10°C rise needs 0.5mm trace width

LED Driver Boards

High-efficiency designs often use multiple parallel traces

Industrial Applications

Harsh environments demand additional safety margins:

| Application | Safety Factor |

|---|---|

| Automotive | +30% width |

| Aerospace | +50% width |

Pro Tip

Always verify calculations with our interactive PCB Trace Width Calculator before finalizing designs.

Common Mistakes

Ignoring Temperature Rise

Leads to premature failure in high-current applications

Overlooking Copper Weight

2oz copper requires different calculations than 1oz

Ready to apply these principles? Use our PCB Trace Width Calculator for your next project.

Back to Blog